The development trend of industrial motor production and manufacturing - high energy efficiency

In recent years, with the development of power electronics technology, computer technology, and control theory, the global industrial motor market has experienced significant growth. With the emergence of rare earth permanent magnet materials and magnetic composite materials, various new and special types of motors have emerged one after another. Due to the increasing emphasis of the international community on energy conservation, environmental protection, and sustainable development, the production of electric motors has become a global direction for the development of industrial motors. Against the backdrop of reducing energy consumption globally, energy-saving policies have been introduced to further accelerate the development of the global industrial motor manufacturing industry.

1. The motor industry is transitioning towards intelligence and energy conservation

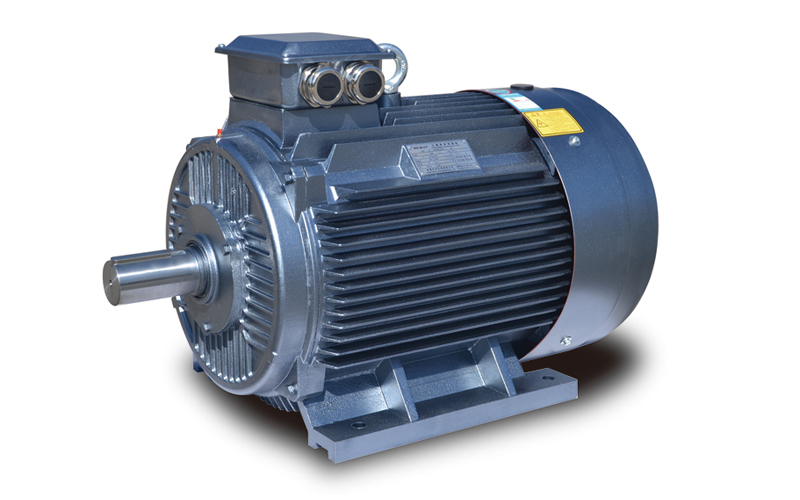

At present, the technology of ordinary low-voltage motors is relatively mature, but there are still many technical barriers in fields such as high-power high-voltage motors, special environmental application motors, and ultra motors. Based on the development trend of the global electric motor market, it is mainly manifested in the following aspects: the industry is developing towards intelligence and integration. Traditional motor manufacturing has achieved the cross fusion of electronic technology and intelligent control technology. The development trend of the motor industry is to continuously develop and optimize intelligent control technology for small and medium-sized motor systems used in the industrial field in the future, and to achieve integrated design and manufacturing of motor system control, sensing, driving and other functions.

2. The development of motor manufacturing towards differentiation, industrialization, and energy conservation

Electric motor products are widely used in various fields such as energy, transportation, petroleum, chemical, metallurgy, mining, and construction. With the continuous deepening of the global economy and the continuous improvement of technological level, the previous situation of using the same type of electric motor for different properties and occasions is being broken, and motor products are gradually developing towards gender, differentiation, and specialization.

In recent years, global environmental policies have provided clear policy directions for improving the efficiency of motors and their control systems. Therefore, the electric motor industry needs to accelerate the energy-saving transformation of existing production equipment, promote green production processes, develop new generation energy-saving motors, motor systems and control products, testing equipment, improve the technical standard system of motors and systems, and focus on enhancing the core competitiveness of electric motors and system products.

3. Optimization design and material selection of energy-saving motors

Energy saving motors use materials and optimized designs to achieve higher efficiency. For example, the higher the aluminum content in the rotor, the higher the slot filling coefficient in the stator, and the smaller the resistance loss. Optimized rotor structure and rotor stator air gap reduce stray load losses. Improve the design of the cooling fan to reduce the wind resistance loss of motor cooling, and use higher quality and thinner steel laminations for the rotor and stator cores, greatly reducing magnetization losses.

3.1 Optimize the size of stator and rotor laminations and the quality of the steel used

Hysteresis loss and eddy current loss together are called core loss, and about 20% of the total loss is caused by eddy current and core saturation. The eddy currents generated in the stack move relative to the constantly changing magnetic field, resulting in significant power loss. Stacked stator cores can reduce eddy current losses, and based on the quality, resistivity, density, thickness, frequency, and magnetic flux density of the iron, eddy current losses can be reduced through more laminations.

Hysteresis loss is generated by the magnetic circuit as the magnetic flux constantly changes. Most of the load materials used in motors are steel used for the stator and rotor cores. By reducing the thickness of the laminations, the magnetic flux density and core loss are reduced. By annealing, better grade laminated steel can be selected to change the grain structure for magnetization, which can reduce hysteresis loss. By increasing the resistivity of silicon containing steel, eddy current losses are reduced, but the silicon content increases mold wear during the stamping process because it increases the hardness of the steel. The damaged steel crystals during the stamping process severely reduce the magnetic quality of the affected volume. Annealing flattens the stack and recrystallizes the damaged crystals during the stamping process, thereby extending the thickness of a thin plate into the stack.

3.2 Using immersion process for stator lamination

Immersing the stator can strengthen the electrical insulation of the stator winding, prevent the influence of chemicals or harsh environments, and enhance heat dissipation. Thermosetting plastics include epoxy resin, phenolic resin, and polyester for impregnating the stator. Immersion involves immersing the stator in the resin for a longer period of time to ensure penetration and protection. Another impregnation method is called vacuum pressure, which uses a tank that is first emptied and then pressurized to achieve penetration of the stator. Extracting air pockets from the electrical winding improves the thermal conductivity of the winding.

3.3 Optimize the design of stator slots to increase the volume of copper that can be inserted to the maximum extent possible

The slot filling rate affects the quality of the stator winding to a certain extent. A low slot filling rate can lead to 60% of the total loss. Therefore, in order to reduce the total loss, the quality of the stator winding must be relatively large, thereby reducing the resistance. Compared to standard efficiency motors, the motor contains over 20% additional copper, and the insulation winding of the stator is placed in the slots of the steel sheet. The cross-sectional area must be large enough to meet the rated power of the motor. In general, induction motors use open or semi enclosed stator slots. In semi enclosed grooves, the opening of the groove is much smaller than the width of the groove, making winding more difficult and manufacturing more time-consuming compared to open grooves. The number of stator slots must be selected during the design phase as it affects weight, cost, and operational characteristics. The advantages of multiple slots are to reduce leakage reactance, reduce tooth pulsation loss, and improve overload capacity. The disadvantages of more stator slots are increased cost, increased weight, increased magnetization current, increased iron loss, poor cooling, increased temperature rise, and reduced efficiency.

3.4 The rotor is die cast using pure aluminum

Customized designed rotors can greatly increase starting torque, reduce conductor resistance, and improve efficiency. Most induction motor rotors adopt a squirrel cage design. Durable and sturdy, with a simple structure and a lower price, but their starting torque is lower. Copper rotors improve efficiency, but manufacturing them is both difficult and expensive.

3.5 The air gap between the rotor and stator reaches

The air gap is the radial distance between the rotor and stator of a standard radial motor. To improve design efficiency, it is necessary to maintain air gaps. The size of the air gap involves the design of the stator, rotor, motor casing, and bearings. All of these will affect the precise alignment of the stator and rotor shafts.

3.6 Using high-performance electromagnetic enameled wires

Magnet or enameled wire is an electrolytic refined copper or aluminum wire that has been fully annealed and coated with one or more layers of insulation. For example, using wires with a total of 12 layers of insulation. Typical insulation films include polyethylene, polyurethane, polyester, and polyimide as the temperature range increases, with temperatures reaching up to 250 ° C. Thicker rectangular or square magnetic iron wires are used for high